Description

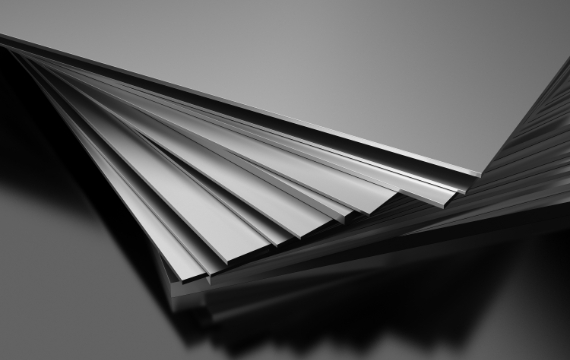

The advantage properties of aluminum alloy have light weight, excellent electrical and thermal conductivity, highly corrosion resistant and ductility.

Aluminum alloy is soft and are usually alloyed with copper, zinc, magnesium, silicon, manganese and lithium to increase strength. Aluminum alloy is exposed to air that instantly forms an anti-oxidant coating to protect products. Aluminum alloy is one of the lightest metals, the application of products ranges from precision technology to daily commodities.

Mechanical Properties

Steel Grade 6xxx Series

Product Specification and Size :

Standard Specification: GB/T 3880, ASTM B209, EN485

| Alloy | Temper |

| 1xxx:1050,1051A, 1060, 1100 | O, H12, H14, H16, H18, H22, H24, H26, H112 |

| 3xxx:3003, 3004, 3005, 3105 | |

| 5xxx:5005, 5052, 5754, 5083 | O, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112 |

| 6xxx:6061, 6082 | T4, T6, T451, T651 |

| 2xxx:2014, 2017,2024 | T351, T451 |

| 7xxx:7075 | T651 |

Alloy designation (For Reference)

Comparison of Alloy Designations for Aluminum flat Products

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | – | – |

| 1050A | – | EN AW-1050A | |

| 1060 | 1060 | – | |

| 1100 | 1100 | – | |

| 2xxx Series | 2014 | 2014 | EN AW-2014 |

| 2017 | – | – | |

| – | – | EN AW-2017A | |

| 2024 | 2024 | EN AW-2024 | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

| 3004 | 3004 | EN AW-3004 | |

| 3005 | 3005 | EN AW-3005 | |

| 3105 | 3105 | EN AW-3105 | |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 | |

| – | 5754 | EN AW-5754 | |

| 5083 | 5083 | EN AW-5083 | |

| 6xxx Series | 6061 | 6061 | EN AW-6061 |

| 6082 | – | EN AW-6082 | |

| 7xxx Series | 7075 | 7075 | EN AW-7075 |

Temper designation (For Reference)

| Temper | Definition |

| F | As fabricated (no mechanical property limits specified) |

| O | Annealed |

| H12 H14 H16 H18 |

Strain Hardened, 1/4 Hard Strain Hardened, 1/2 Hard Strain Hardened, 3/4 Hard Strain Hardened, Full Hard |

| H111 H112 |

Annealed slightly strain hardened (less than H11) Slightly strain harden from working at an elevated temperature or from limited amount of cold work |

| H22 H24 H26 H28 |

Strain Hardened and Partially Annealed, 1/4 Hard Strain Hardened and Partially Annealed, 1/2 Hard Strain Hardened and Partially Annealed, 3/4 Hard Strain Hardened and Partially Annealed, Full Hard |

| H32 H34 H36 H38 |

Strain Hardened and Stabilized, 1/4 Hard Strain Hardened and Stabilized, 1/2 Hard Strain Hardened and Stabilized, 3/4 Hard Strain Hardened and Stabilized, Full Hard |

| T351 | Solution heat-treated, cold worked, stress relived by stretching and naturally aged |

| T4 T451 |

Solution heat-treated and naturally aged Solution heat-treated, stress relived by stretching and naturally aged |

| T6 T651 |

Solution heat-treated and then artificially aged Solution heat-treated, stress relived by stretching and artificially aged |

Available Size Range

| Dimension | Range |

| Thickness | 0.5 ~ 6.0mm for sheet 6.0 ~ 120mm for plate |

| Width | 900 ~ 2,200mm |

| Length | 2,000 ~ 10,000mm |

– Standard Width and Length: 1000x2000mm, 1250x2500mm, 1500x3000mm, 1219x2438mm, 1524x3048mm

– Surface Finish: Mill finish, unless otherwise specified

– Surface Protection: Paper interleaved, PE/PVC filming (if specified)

Application

Aluminum sheet or plate is used in the various applications, including aerospace, military, transportation, etc. Aluminum sheet or plate also used for tanks in many food industries, because some aluminum alloys become tougher at low temperatures.

| Type | Application |

| Food Packaging | Beverage can end, can tap, cap stock, etc. |

| Construction | Curtain walls, cladding, ceiling, heat insulation and venetian blind block, etc. |

| Transportation | Automobile parts, bus bodies, aviation and ship-building and air-cargo containers, etc. |

| Electronic Appliance | Electrical appliances, telecommunication equipment, PC board drilling guide sheets, lighting and heat radiating materials, etc. |

| Consumer Goods | Parasols and umbrellas, cooking utensils, and sports equipment, etc. |

| Other | Military, color coated aluminum sheet |